Brominated flame retardants are an important additive in the chemical industry, playing a fire-resistant role by slowing down the combustion rate of materials and suppressing flame spread. Due to their efficient flame-retardant performance and cost-effectiveness, they are widely used in multiple industries. This article will delve into the upstream raw materials, production process, and downstream applications of brominated flame retardants, aiming to provide readers with comprehensive and professional knowledge.

Before introducing upstream raw materials, let’s first understand brominated flame retardants. These flame retardants usually contain bromine elements, which can release hydrogen bromide or other brominated compounds when heated. These substances can capture free radicals, thus interrupting the chain reactions in the combustion process. This mechanism extends the ignition time of materials and reduces the flame propagation speed, achieving flame retardant effects.

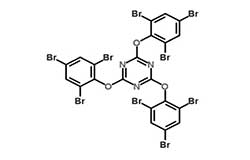

Regarding upstream raw materials, the production of brominated flame retardants primarily depends on bromine sources and the corresponding synthesis processes. Common bromine sources include inorganic salts such as potassium bromide and sodium bromide, as well as some organic bromides. These raw materials are converted into various brominated flame retardants with different structures and functions during chemical synthesis. For example, Decabromodiphenylether (BDE-209) is a widely used high-efficiency brominated flame retardant, produced by the substitution reaction of diphenyl ether with hydrogen bromide under the action of a catalyst.

The production process involves a series of chemical reactions and post-processing steps. First, raw materials need to be accurately measured and mixed, then reacted under specific temperature and pressure conditions. After the reaction is completed, steps such as filtration, washing, and drying are needed to remove by-products and impurities, ultimately obtaining pure brominated flame retardant products. Throughout the production process, environmental control is crucial to ensure product quality and production efficiency.

In terms of downstream applications, brominated flame retardants are widely used in plastics, textiles, electronic and electrical equipment, building materials, and other fields.

In plastic products, brominated flame retardants can be used to enhance the flame resistance of materials such as polycarbonate, polypropylene, and polyurethane. In the textile industry, post-treatment technologies can give fabrics good flame retardant properties. In electronic and electrical products, the use of brominated flame retardants can ensure that components such as wires and circuit boards do not easily catch fire when exposed to fire sources, thereby improving safety. Despite their excellent performance, the environmental and health impacts of brominated flame retardants have also raised widespread concern. Some brominated flame retardants may decompose and release toxic substances under certain conditions. For example, polybrominated diphenyl ethers (PBDEs) have been shown to have bioaccumulation potential and potential neurotoxicity. Therefore, the research and development of environmentally friendly and non-brominated flame retardants have become current research hotspots, in hopes of finding safer and more environmentally friendly alternatives.

As an important bromide chemical product, brominated flame retardants reflect the progress of chemical technology and the challenges of environmental protection in their upstream and downstream applications. In the future, with the development of science and technology and the improvement of safety and environmental protection requirements, the research and development of new environmentally friendly flame retardants will be an important direction for industry development, providing stronger safety assurances for people's life and property.

This is the last one.