Although phosphorus-nitrogen flame retardants and inorganic flame retardants are currently research hotspots in halogen-free flame retardants for plastics, brominated flame retardants still cannot be completely replaced due to their high flame-retardant efficiency and wide applicability. To reduce the environmental pollution, human toxicity, and ecological damage caused by brominated flame retardants, many environmentally friendly brominated flame retardants by brominated flame retardants supplier have been developed. These are mainly polymeric brominated flame retardants and reactive brominated flame retardants.

The brominated epoxy resin has excellent self-extinguishing properties, thermal stability, good light stability, flame retardancy, and high melt flow rate. Initially developed and promoted by Tokyo Shibaura Electric Co., Ltd. in Japan, it is mainly used in electronic potting materials. With the emergence of the "dioxin" problem, the environmental issues of traditional brominated flame retardants have gradually drawn attention. Brominated epoxy resin, as a product of upgrading, has begun to be promoted and applied. It has currently become an important substitute for decabromodiphenyl ether, mainly used in flame-retardant PBT, polyolefins, PC/ABS alloys, and other polymers. When combined with antimony trioxide, containing about 12% of both, it can make materials like Nylon 6 and polyester achieve UL94 V-0 grade.

Brominated polystyrene is an additive-type polymeric brominated flame retardant that appears as white or light yellow powder, is insoluble in water, has a bromine content of over 65%, and a thermal decomposition temperature of over 310℃. Its molecular structure is a long-chain macromolecule, featuring high thermal stability and good compatibility with high polymers. More importantly, it does not produce carcinogens like dioxins when burning, making it an excellent environmentally friendly brominated flame retardant.

As an internationally recognized environmentally friendly brominated flame retardant, brominated polystyrene is widely applicable to engineering plastics like PBT, PET, thermoplastics, and some plastic alloys (e.g., PC/ABS).

Brominated polystyrene can be combined with antimony trioxide or organic phosphorus-nitrogen flame retardants to provide excellent flame-retardant performance.

Poly(pentaerythritol tetrabromophthalate ester) is another excellent type of polymeric brominated flame retardant, with a high bromine content (around 70%). It can be synthesized into products with different molecular weights according to the flame-retardant requirements of materials, featuring high flame-retardant efficiency, excellent thermo-chemical stability, and electrical properties. It does not result in frost or migration, has excellent processing performance, reduces, or inhibits the dripping phenomenon of resins during combustion, and does not release dioxins and other carcinogens, meeting environmental protection requirements.

Brominated styrene-butadiene-styrene copolymer (SBS) was developed and promoted by Dow Chemical in 2012 as a new type of macromolecular brominated flame retardant. The United States Environmental Protection Agency (EPA) has determined that brominated SBS can replace hexabromocyclododecane, and it is currently being industrially produced. Brominated SBS has a molecular weight of approximately 100,000, features no blooming or migration issues, does not bioaccumulate, and due to its structural similarity with polystyrene, it can be widely used in flame-retardant polystyrene and other polymers.

Reactive brominated flame retardants partake in polymerization reactions in the form of monomers during polymer synthesis and become part of the polymer, forming corresponding block or graft copolymers. They ensure that the newly synthesized materials have excellent flame-retardant properties while making minimal changes to the original thermal and mechanical properties of the resin, thereby reducing blooming or exudation and having a minor environmental impact.

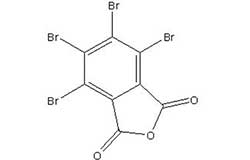

Pentaerythritol tetrabromophthalate ester is a reactive brominated flame retardant with a bromine content of about 71% and high flame-retardant efficiency. The presence of benzyl ester groups allows this bromide chemical product to have good compatibility with polymer matrices, ensuring no frost or migration. Additionally, its good UV absorption provides materials with excellent light stability. Pentaerythritol tetrabromophthalate ester can also serve as a monomer to further synthesize poly(pentaerythritol tetrabromophthalate ester).

Dibromoneopentyl glycol, a diol structurally, can replace polyols and react with dicarboxylic acids or diisocyanates to form different resins with varying degrees of unsaturation and bromine content.

As a reactive flame retardant, dibromoneopentyl glycol is primarily used in flame-retardant polyurethane foams. Due to its structural characteristics, the resulting polymers have excellent flame-retardant properties without significantly affecting the light stability of the final products. It can also be used as an additive flame retardant for ultra-high molecular weight polyethylene and expandable polystyrene. Additionally, it can act as an intermediate for synthesizing dibromoneopentyl glycol phosphate esters and borate esters, which have higher molecular weight and better exudation resistance, and are also highly effective flame retardants.

Tribromoneopentyl alcohol has a high bromine content and excellent photothermal stability. It is a downstream product of dibromoneopentyl glycol and can also be obtained via the reaction of pentaerythritol. As a reactive flame retardant, it is widely applicable in elastomers, coatings, and foams.

This is the first one.