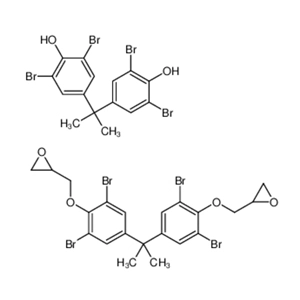

Brominated epoxy resin has the advantages of high thermal stability, good aging performance, excellent processing performance and no corrosion. Suitable for PBT, PET and other thermoplastic plastics.

Appearance: Light yellow powder or granule

Bromine content: 51-53%

Moisture: ≤0.10%

Specific gravity: 1.8g/cm3

Softening point: 140-150℃

Chromatic value: ≤100Apha

Average molecular weight: 25,000

| Quality Standard | |

| Appearance | Light yellow powder or granule |

| Bromine content | 51-53% |

| Moisture | ≤0.10% |

| Specific gravity | 1.8g/cm³ |

| Softening point | 140-150℃ |

| Chromatic value | ≤100Apha |

| Terminate | ~ |

| Average molecular weight | 25,000 |

Brominated epoxy resins are mainly applied in the field of electronics and electrical appliances. They are crucial flame-retardant materials for printed circuit boards, effectively preventing fires caused by short circuits. Besides, they are also used in some high-end electrical appliance casings and electronic component encapsulation materials, meeting strict flame-retardant standard requirements and ensuring the safe use and reliability of electrical equipment.

Bromx Chemical Industry Co., Ltd.

Look For A Professional Bromide Supplier?

Related Brominated Flame Retardants